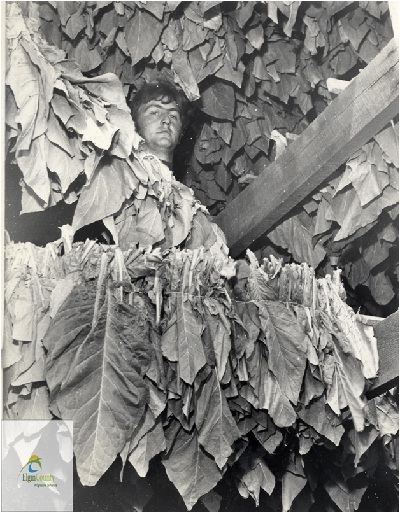

Flue-Curing

The green tobacco leaves are hung in a kiln where they are treated with heat for about six days, by which time they will turn a desired yellow. John Zamecnik of RR 2, Vienna started priming about a week early in July 1971. Seen here, hanging the tobacco in the kiln, is Gilles Menard of Hawkesbury, one of eight people hired to help with the harvest.

St. Thomas Times-Journal fonds, C8 Sh2 B2 F4 56b.

Early-August to Early-October

Flue-cured tobacco is named after the process which uses ducts or flues to conduct heat from the furnaces throughout the kiln. Older furnaces used coal or wood, but newer furnaces ran on oil or natural gas. Curemen used to come up to Ontario from the tobacco belt of the Southern United States to watch over the process, but farmers learned how to successfully cure tobacco themselves. The process involves a careful control of heat and humidity:

Yellowing the Leaf (20 to 40 hours)

-too much heat or too little humidity results in green tobacco

-yellowing too long results in useless "dead" leaves

Drying the Leaf (2-4 days)

-too much heat or too rapid an increase in heat blotches or scalds the leaf brown

-too slow an increase in heat or too much humidity also creates "dead" leaf

Factors to watch during the curing process include:

-moisture in the leaves when they were primed

-ripeness of the leaf when it is put in the kiln

-weather conditions which can affect temperature and humidity inside the kiln

Once the leaves are dried (confirmed by checking the stems, the last part of the leaf to dry) the tobacco is allowed to cool and the doors to the kiln are opened in order to allow the humid night air to case or soften the dry leaves. The leaves are then moved to the pack barn. The curing process is repeated until the entire harvest has been taken in. The harvest can end as late as October if there was a late start in planting earlier in the year.

Tobacco in

Elgin County :

Production :

- Preparation

- Transplanting

- In The Field

- Harvest

- Into the Kiln

- Flue-Curing

- Baling

- Crop Damage

- The Workers