Building a Ford Falcon

Assembly Continues

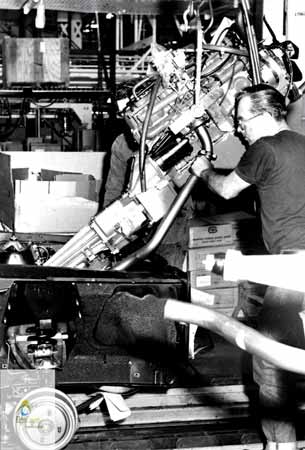

C8 Sh4 B2 F1 44a

"The engine and transmission is 'decked' into the body to be connected to the drive shaft."

C8 Sh4 B2 F1 44b

"The steering wheel, complete with flasher signals and gear shift lever, is put in place."

C8 Sh4 B2 F1 44c

"Wheels and tires are installed to the brake hub as the production line progresses."

C8 Sh4 B2 F1 44d

"Here the 'dressed up' fender, complete with headlights and other components join the Falcon."

C8 Sh4 B2 F1 44e

"Riding on a clamshell carrier, the Falcon joins an overhead conveyor system. The carrier permits free access around the car for future assembly operations."

C8 Sh4 B2 F1 44f

"Here an assembly worker installs the door handle and lock assembly."

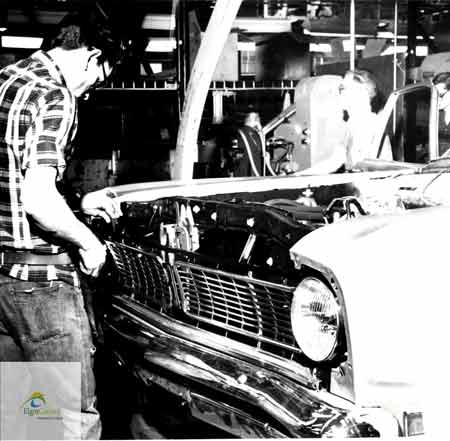

C8 Sh4 B2 F1 44g

"Nearing completion by the minute, the Ford Falcon receives its front grille as it continues through the assembly plant's chassis department."

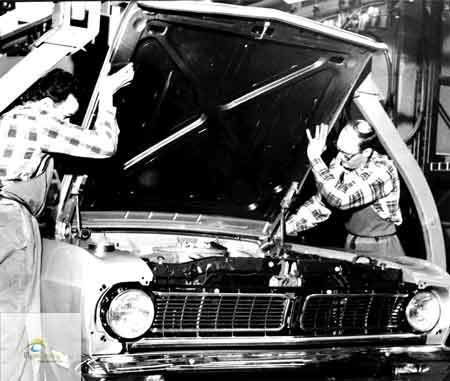

C8 Sh4 B2 F1 45a

"Practised hands guide the hood into position so that it can be attached to the hood hinges."

C8 Sh4 B2 F1 45b

"The radiator is automatically filled with anti-freeze."

C8 Sh4 B2 F1 45c

"Engine and power train are checked on the dynanometer test rolls. This is, in effect, a simulated road test."

C8 Sh4 B2 F1 45d

"At this stage, Falcons are automatically loaded into the selectivity tower for storage prior to trim operations."

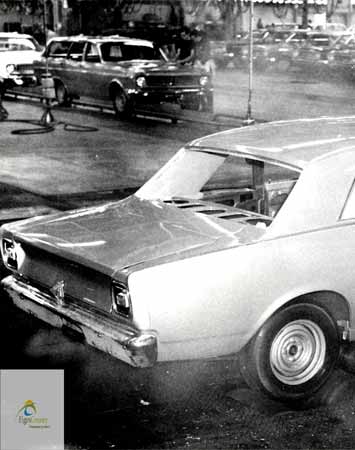

C8 Sh4 B2 F1 45e

"Moving under its own power, the Falcon leaves the clamshell carrier at the end of the chassis department operations."

Previous | Back to Top | Next